By Caleb Cass PE, Director of Engineering

When high accuracy stockpile measurements are not performed regularly, you can expect problems to arise. Paying too much for material that wasn’t delivered, accumulating financial expenses, and not having material on-hand when needed are just some of the headaches solid waste sites experience. These issues can often be avoided by using competent service providers who have invested in modern technology and processes. The hardware and software exist today for company employees from all departments to see and understand how these measurements are performed.

Problem

At Firmatek, we complete over 2,600 stockpile measurement jobs every year, some with over 200 individual stockpiles at a single site. What we’ve seen is that using truck counts to track, bill and pay for bulk material delivery can cause the billing quantities to be off by as much as 20%. This is due to a few factors, but the two main ones are variations in the loading level from truck to truck and the difference in material density between the source, the truck and the delivered pile.

As truckload after truckload of material is brought in and dumped into piles over time, the error accumulates, potentially creating a large value of material recorded on the financials that does not exist in the pile sitting on the ground. Eventually, the discrepancy between what is physically in the pile and what is on the books gets so obvious that the material value has to be “written off” as a loss to the site.

Beyond the financial concern is the problem that the material is actually needed for landfill construction and operation. It’s very important to know with confidence how much is on hand in the stockpiles so that there are no delays or emergency expenses caused by the material running out.

Solution

The best practice for managing bulk material inventory is to have the stockpiles on site measured regularly by an experienced company that specializes in this niche service. This may not be the same service provider who is competent in performing other tasks like setting aerial control targets, performing certification surveys or laying out a landfill gas collection system.

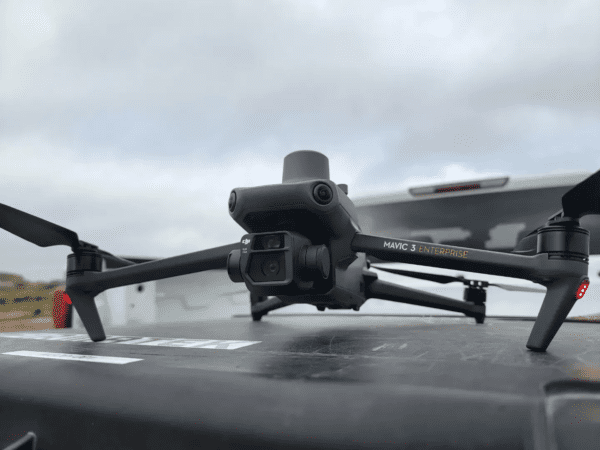

The surveying and mapping industry has seen huge innovations over the last ten years that allow for stockpile measurement to be performed quickly, accurately, safely and affordably. Collecting data on site with Lidar used to be too expensive to justify for small jobs, but now laser scanners (Lidar) are much more common and can be mounted to everything from trucks and ATVs to drones and backpacks. This means that using high accuracy Lidar point clouds to measure the volume of material in a stockpile is now very common. A good example is the mining industry, which has embraced the use of laser scanning to measure the hundreds of thousands of aggregate stockpiles that make up their on-hand inventory. The development of drones that produce professional quality topographic data and high resolution ortho imagery is quickly changing the way owners acquire and use this type of geospatial data. With all of the cutting-edge hardware options available to increase accuracy and reduce risk, there’s no reason to be collecting mapping data using outdated tools and techniques.

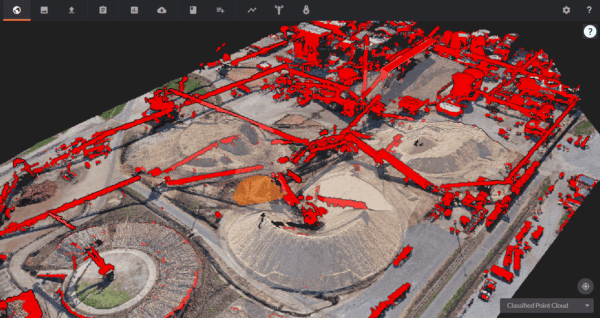

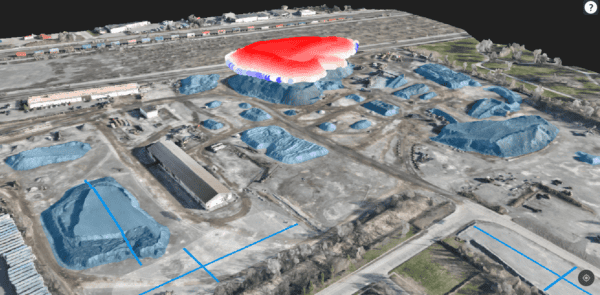

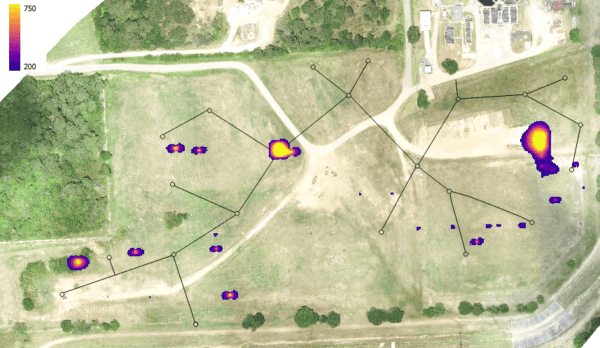

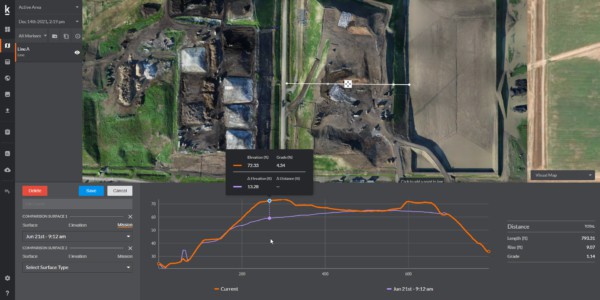

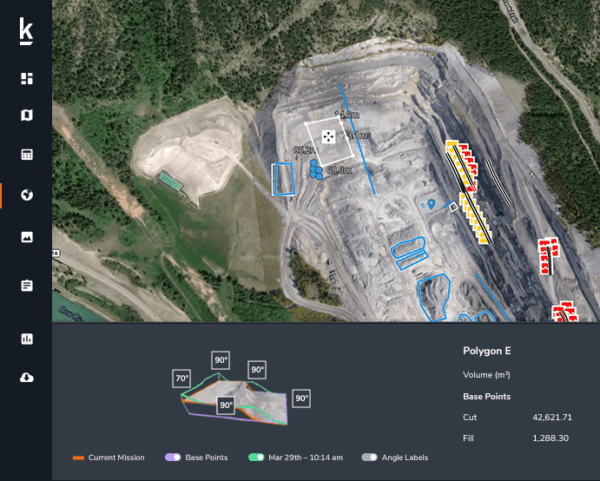

Along with modern hardware to capture the data, software has also evolved to meet the demands of larger, denser, high resolution datasets. This software allows for the real world, including stockpiles, to be modeled and inspected in ways that were never available before. We can now see where a single bucketload of material has been taken out of a stockpile, or where rain has created runoff and material has built up around the base. These models are built from millions of data points that precisely capture every detail of the surface. Being able to see and process the data with this level of detail allows us to compare pile surfaces from one survey to the next to show where areas have been cut or filled and to accurately define the base of the pile using the natural variations of the surrounding topography.

That data and the accompanying software should be integrated with all of the previous CAD design and survey work that has been done on site. Even though the hardware and software they are using may be new, service providers should be able to work collaboratively with other products and deliverables that have already been generated. This means that stockpiles can be measured from “toe to peak” using the surrounding grade. They can also be measured against CAD-generated bases and against previous surveys from other companies.

Service providers are able to visually show how the volumes were calculated if they use the right tools and perform the work properly. At Firmatek, we schedule a live webinar with our clients where we screen share our software and walk through our workflow. Using this digital 3D environment, we review the data that was collected, the surface models that were generated, the bases that were used and any changes over time that are affecting the results.

Summary

Not knowing the amount of material that is in bulk material stockpiles can create large financial and operational problems for solid waste sites. These problems usually start small and accumulate over time until they are bad enough to have a large impact. With modern hardware and software, performing accurate measurements regularly is more cost-effective and accessible than in the past. The solution is to find a service provider who is experienced and specializes in measuring bulk materials. These companies will use state of the art technologies to capture accurate data quickly and accurately. They’ll also use processing software that allows them to clearly visualize the data in a 3D environment, pulling in data or files that have been generated previously, and creating their own models when needed. In the end, the client should have a clear understanding and be comfortable with the way the stockpile volumes were calculated.

About Caleb Cass

About Caleb Cass

Caleb is a civil engineer who lives in San Antonio, Texas and works on projects throughout the country. He started his career as a field inspector for one of the ten largest construction contractors in the U.S. and then went on to spend five years performing engineering design for a national consulting firm. Caleb now works for Firmatek and has spent the last five years performing engineering, mapping and consulting work primarily for mining, solid waste and engineering clients. Caleb graduated in 2007 from the University of Texas at El Paso with a Bachelor of Science Degree in Civil Engineering and became a licensed Professional Engineer in Texas in 2012. Connect with Caleb on LinkedIn.