Firmatek has been measuring stockpiles and helping the Aggregate Mining Industry manage its inventory for almost 30 years. We have all used a variety of different technology over the years. It is not just Firmatek’s legacy of innovation, but also the industry’s, that has taken us from a wheel and tape, to GPS poles, to lasers, and now to drones. With each evolution in the technology, there have been improvements in everything from accuracy, to safety, to management systems. Let’s take a look back at how we got to where we are today.

A Blast From the Past

In the early days of Firmatek, when we were brought in as an independent third party to measure stockpiles, we were often replacing an internal wheel and tape or manual measurement. This method is still used today in some organizations and requires an employee to walk around the pile with a wheel and tape measure, collecting the circumference of the base of the pile. The height of the pile is guestimated or a rangefinder can be used to find the height. Then the volume is calculated. This process is not very accurate, and in addition it can be dangerous to walk on and around piles.

The next technology used, that we still see frequently, is a GPS Base and Rover. Often this is what survey crews are using when they are measuring the piles. With this method, a surveyor or employee walks around and on top of the piles recording GPS points. Those points are imported into software, and the volumes are calculated. While this process is more accurate than the wheel and tape, it is limited because of the small number of points that are taken to create the volumes. It is also more dangerous than other methods as it requires walking on the stockpiles.

Innovation at Firmatek

Firmatek started out with the first kind of laser scanning. We used reflector-less lasers, like the Quarryman, to point and shoot piles, collecting one data point at a time. By setting up in multiple positions around the stockpiles and sites, we would collect thousands of points and piece it together to create a full data set. This data set would be put into software to calculate the volumes of the piles. This method was tedious, but it produced more accurate results due to the increased amount of data and therefore, fewer assumptions.

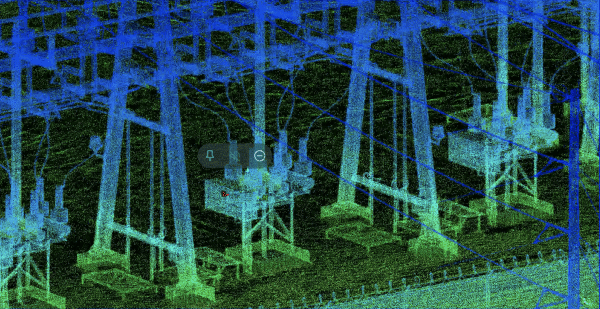

Firmatek then moved from tripod mounted lasers to mobile LiDAR scanners. Founder, Jay Heck, actually helped develop one of the ones we still use today, the Dynascan. Firmatek had serial number 001. Introducing LiDAR to the industry to measure stockpiles brought even more accuracy, and the ability to truly visualize the site in 3D for the first time. LiDAR, along with our software packages, gave us the ability to show our clients the data in 3D and walk through their piles and question with them. This was a huge advancement in accuracy, understanding, and management of inventory. For the first time, clients could really see what was going on and how their piles had changed. It was also an improvement in safety, as the team no longer had to walk around on piles. Instead, they could get the data they needed by driving around in the truck.

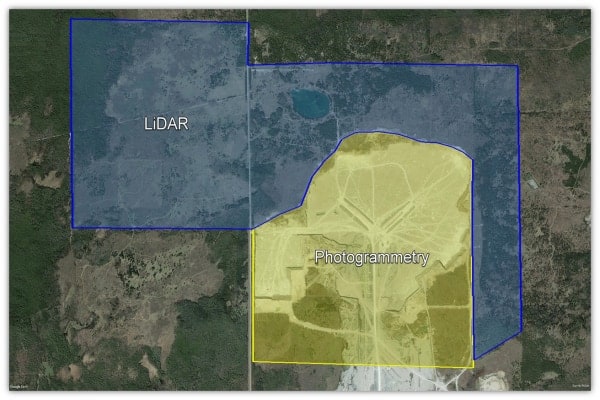

It is worth mentioning that there is another popular method of inventory measurement that Firmatek has never performed: the manned aircraft aerial survey. In this method, a plane flies over the site or sites to be measured taking pictures. The images are processed in photogrammetry software and tools are used to find the volumes. This technology and process was an improvement over the reflector-less lasers and other previous technology as it created a denser point cloud. However, it is not as accurate as LiDAR, and can be very expensive depending on the size and number of the areas being mapped.

Current Technology

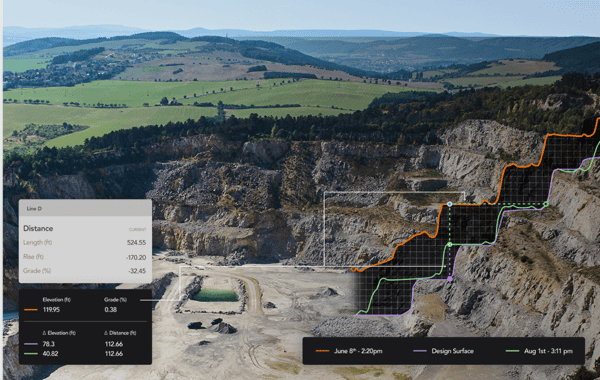

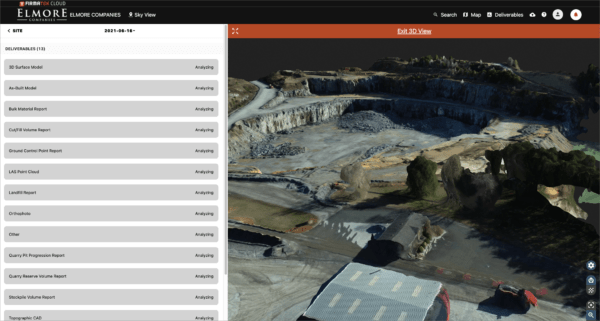

Finally, we get to the current technology: Drones. There are a number of options here, and a number of ways to go about implementing drones into your operation. But regardless of what you choose, drones offer a new and exciting way to measure and manage inventory. Drones fly autonomously, capturing dense point clouds, and when used with Ground Control or RTK technology, they give accurate measurements. The ability to visualize your operation is improved by being able to see and compare ortho images and by being able to view your point cloud or data with RGB values. Drones are a cost effective way to get frequent and accurate inventory measurements, thus helping you manage your inventory better.

Firmatek continues to evaluate new technology and bring the best solutions to market in the aggregate mining industry. From introducing the industry to laser stockpile measurement, to enterprise drone solutions, Firmatek has been at the forefront of technology. So what’s next? LiDAR on drones is on our radar, as are various types of sensors to help with things like inspection. We’ll keep researching and partnering with clients to test new solutions. Together, Firmatek and the Aggregate Mining Industry will continue our legacy of innovation.