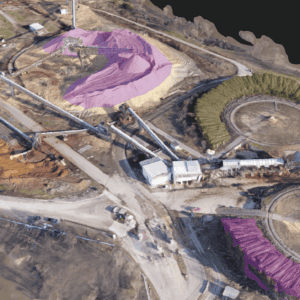

Leveraging regular, aerial drone landfill surveys provides timely compaction and airspace measurements, helping teams plan for new construction and capital expenditure.

Challenge

Firmatek’s landfill client had the ability to better utilize airspace by improving the compaction of incoming material. The amount of compaction that could be achieved is known as density, which was a key metric for landfill operators. The higher the density, the more waste they could bring in and charge for, resulting in a higher revenue without changing other factors like capital investment. Prior to working with Firmatek, this landfill was conducting annual surveys, which posed several risks. They had less information about remaining airspace which could have led to overfill beyond permitted capacity. They also had less control when it came to planning for the construction of new cells. Waiting too long to build new cells could stifle earning potential, while building them too early would mean unnecessary capital expenditure and empty infrastructure.Solution

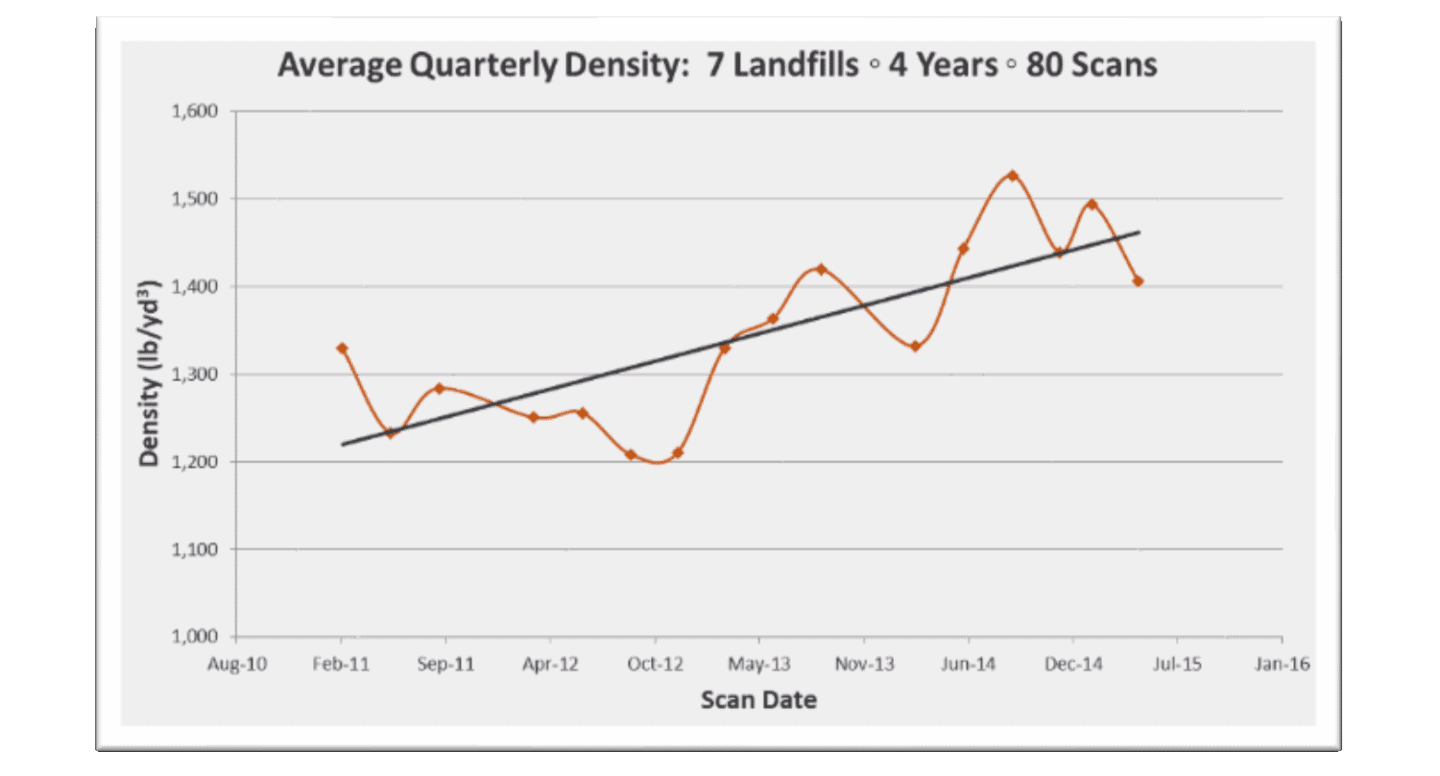

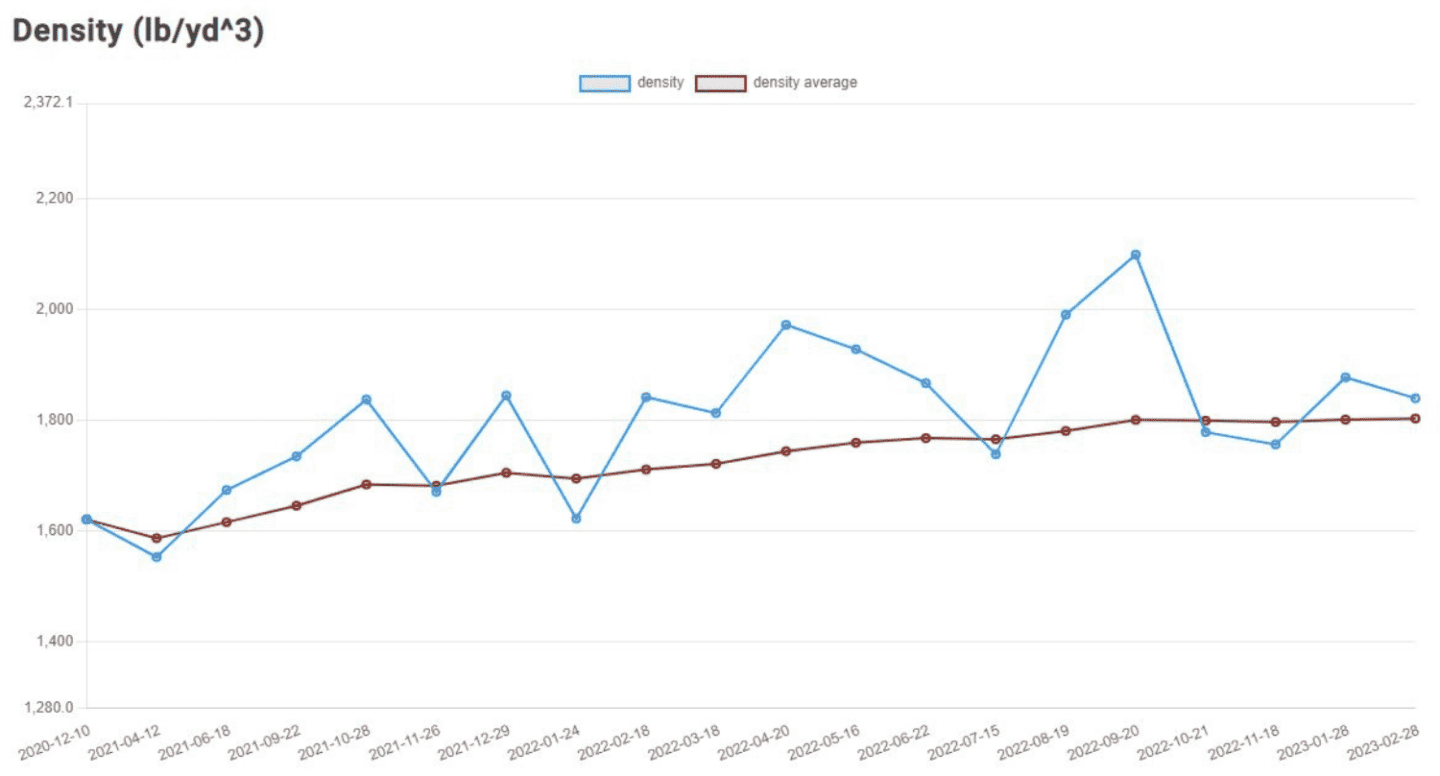

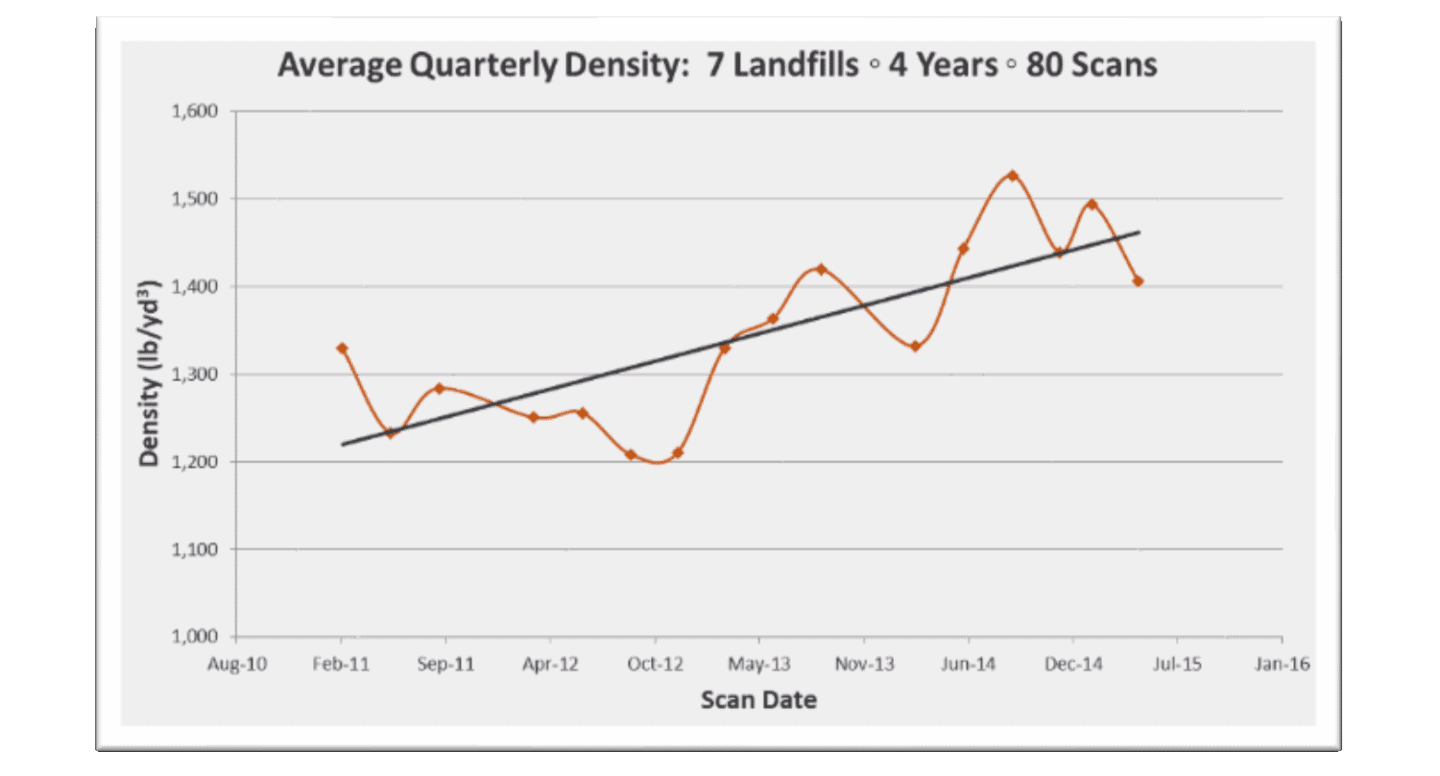

By performing quarterly or monthly drone flights, Firmatek was able to measure the compaction density of the site on a regular basis and provide timely information to the client’s engineering and operations teams. Based on those numbers they were able to make the necessary changes to operations, equipment, or systems to quickly correct any negative trends and continue to increase their compaction density. With regular measurement, Firmatek was also able to monitor remaining airspace which allowed landfill management to forecast the need for new cell construction much more accurately. This helped the client avoid premature cell construction and the associated costs and ensure that the site wouldn’t be in danger of running out of airspace. This frequency of monitoring also enables the client to catch overfill more quickly, avoiding the cost of having to excavate, move, refill and recompact the waste into a permitted area. Teams were able to access information any time, from anywhere using our Kespry Cloud platform. This helped democratize the information among landfill decision makers, ensuring they could take immediate action to address any issues that surfaced.Results

Every year Firmatek helps detect overfill on sites during their quarterly or monthly airspace measurements. The sooner this issue is detected, the less work and cost required to mitigate the problem. If sites are conducting annual measurement, then a whole year’s worth of fill could potentially be placed incorrectly and need to be excavated, moved, and replaced. Increasing the frequency of density measurements to at least quarterly has resulted in an increased compaction density and improved airspace utilization by 13% over the course of three years and as much as 20% over seven years, which had a significant impact on the client’s business.