Firmatek’s ability to offer a faster, safer and more accurate inspection solution for a fraction of the cost helped Sulphur Springs Velley Electric Cooperative gain an advantage on wildfire hazard.

Challenge

Sulphur Springs Valley Electric Cooperative (SSVEC) services areas of Arizona that are prone to wildfires given the dry climate and extreme temperatures. Vegetation encroachment, failing utility equipment, and hotspots can increase wildfire hazard significantly, and ground inspections conducted with bucket trucks don’t typically have the speed or capability to detect the extent of repairs that need to be made prior to summer heat.

Ground inspections have other limitations beyond time requirements as well. First and foremost, it puts more employees at risk by sending linemen up in bucket trucks and exposing them to potential hazard. Second, off road or remote utility pole placements may be cumbersome or dangerous to access. And third, they’re more expensive to deploy.

Solution

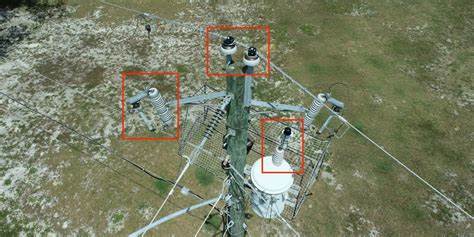

In January of 2024, SSVEC partnered with Firmatek to proactively inspect over 8,400 utility poles in across Benson, Sierra Vista and Wilcox. The utility company recognized that using aerial drone technology would increase speed and improve issue identification by gaining a top-down view of each pole. With thorough inspections and a library of image assets, SSVEC gained the information they needed to prioritize pole repairs that could contribute to wildfires.

While ground inspections typically take 15-10 minutes per pole, Firmatek was able to inspect one pole every 20-30 seconds with drones. In addition to collecting data on hazard and reliability mitigation, the inspection also updated SSVEC maps and data systems with the latest and most precise information, helping the local cooperative respond faster to outrages and maintain its system.

Result

Firmatek was able to provide a safer, faster, and more accurate inspection solution for SSVEC for a fraction of the cost. By moving from ground to aerial drones, the company was able to increase their inspection rate from 12-15 poles per day to 200-300 poles per day, which is a 1,200-1,900% increase.

View more coverage of SSVEC’s efforts to boost service reliability and community safety:

- Innovative drone program takes flight at SSVEC for wildfire prevention

- A bird’s-eye view: Sulphur Springs Valley Electric Cooperative using drones to help identify repairs