Proving the Value of Aerial Inspections for Electric Utilities

Increasing efficiency, reducing SAIDI time and improving the business bottom line.

Challenge

Firmatek’s electric utilities client had a goal of achieving higher reliability by reducing System Average Interruption Duration Index (SAIDI) time to at or below 60 minutes. With their current approach of using ground line inspections, they were hovering around 107 minutes and had meaningful room for improvement. Ground line inspections were limited in what they could achieve given they were timely to conduct, often required additional equipment and manpower to confirm issues, and put employees in harm’s way. They needed a faster, safer, and more efficient way to inspect utility pole conditions to make impactful decisions that would support business KPI’s.

Solution

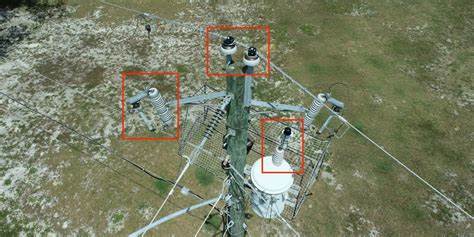

Firmatek started with a proof of concept on one substation, using aerial imagery to perform a comprehensive visual inspection and gather a wealth of data. Using a drone reduced man hours, improved safety, and streamlined logistics. Compared to traditional ground line methodology, we were able to inspect 100 poles in ¼ of the time, which greatly improved efficiency. We were also able to provide the client a better perspective and vantage point of how and when infrastructure was failing, helping them prioritize the most critical locations and take proactive measures to reduce failure and downtime.

Results

After demonstrating an average of 53% improvement in SAIDI time across the first substation’s four feeders. Firmatek went on to scale up survey efforts and demonstrate a system wide improvement of 68% over five years. We focused on the first 20 worst-performing feeders in year one, working up to a total of 70 feeders by year five, helping them reduce SAIDI time to around 35 minutes, which far exceeded their goal of 60 minutes.

The aerial data collected was also applicable to other parts of the business such as engineering and operations. By identifying trends, they could make improvements to the types of materials they were using as well as replacement and repair cadences. The data set brought new insights that were otherwise unable to be captured through ground inspection, then these insights were democratized throughout the organization to support future decision making and continue to improve the business bottom line.