Albert Einstein is credited with saying “the definition of insanity is doing the same thing over and over again, but expecting different results.” By this definition, I think we are all a little insane sometimes. It’s a good reminder to be proactive and make necessary changes, even if they are painful.

As we head into the busy inventory season, it necessary to assess best practices, and in some cases make adjustments to how you manage your inventory. Occasionally, we get a client who continues to ignore an inventory problem, or one who does not make any adjustments to a process that resulted in large adjustments in the past. This inevitably results in an inventory measurement that is not what the client had hoped for. We covered this in our blog, The Cost of Not Measuring Your Inventory, a couple of weeks ago.

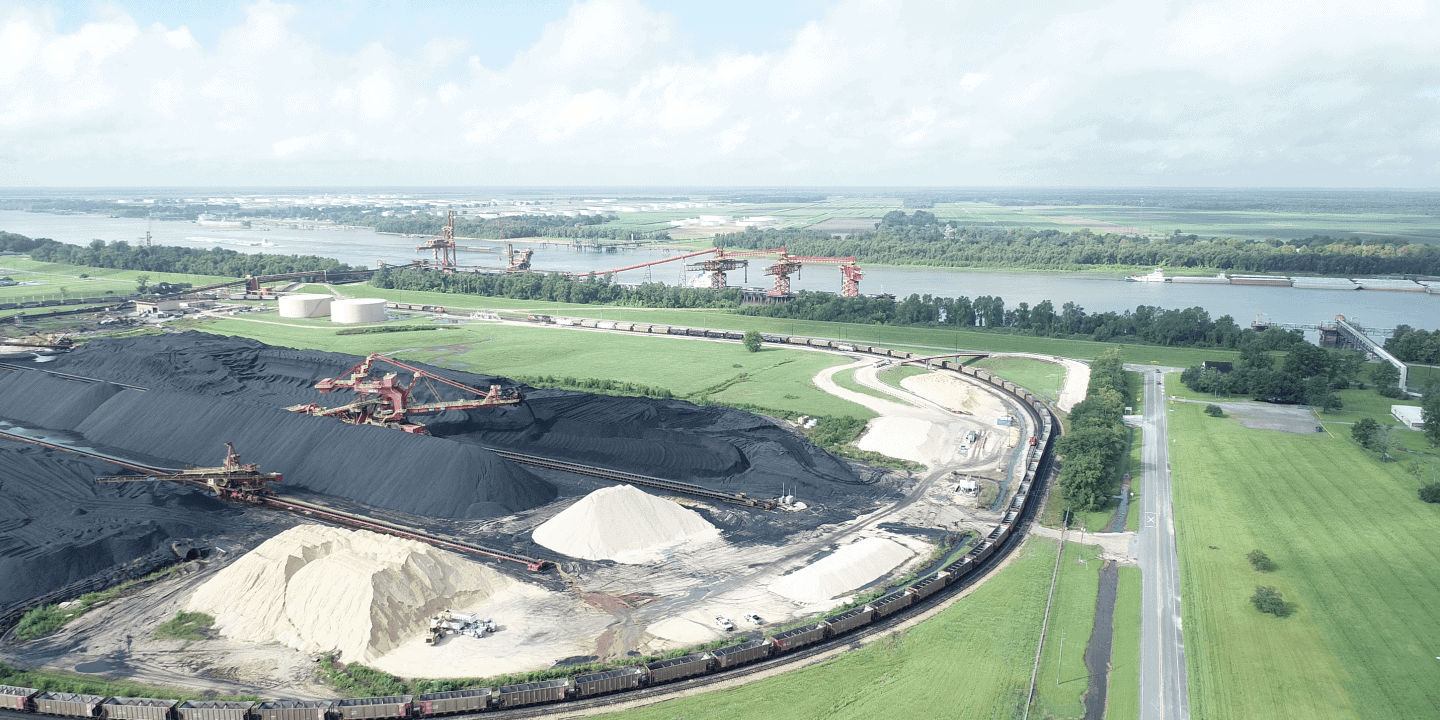

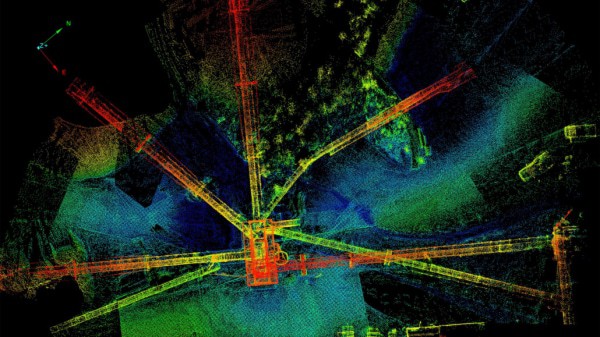

We have faced these issues many times with clients. Firmatek is the industry leader when it comes to measuring and helping our clients manage their inventories. We have been helping clients manage inventory for a long time – almost 30 years. But we have to be honest, a client’s inventory issues do not start and stop with the inventory number that they see in their report. Sometimes, they do not like the number they see in the report (see also The Truth Hurts). But that does not always mean that the numbers are wrong. Sometimes, it means there is a problem that has been “wished” away that did not go away on it’s own.

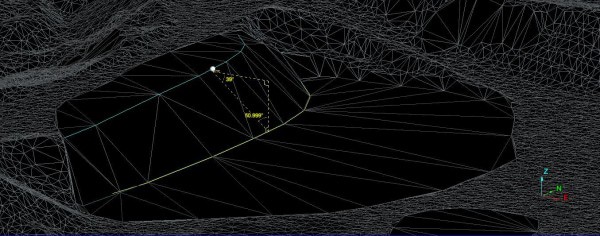

For many, the discrepancies in inventory rest in making a simple adjustment to the ledger. What we are talking about is the reported production on the plant side compared to the inventory results that we deliver. We see a wide range in the way that people choose to manage their inventory. One thing we do not recommend is this: adjusting your inventory according to the results of a measurement and then hoping that the discrepancies magically go away by the time the next measurement is conducted. It is rarely successful, no matter how many times you try it. Doing the same thing and expecting different results doesn’t work.

Instead, we recommend being proactive in your inventory process. If there are always discrepancies in your inventory, adjustments must be made to your processes. This is not just about book adjustments, but rather adjustments must be made on the production and process side so that you can correctly account for your inventory internally. At Firmatek, we refer to our best practices, and we work with clients to help them develop their own. You can learn more about how we think about inventory measurement in our Aggregates Inventory Measurement 101 Guide.

So this time around, let’s decrease the level of insanity and be proactive about inventories. Firmatek is here to give you more than a number to put on your books. Let’s work together to improve inventory management at your location.