For waste engineers, landfills are an ongoing challenge that require frequent measurement and the application of constantly evolving maintenance techniques.

After all, once tons upon tons of waste accumulate the maintenance challenges take on a life of their own. Liquid runoff must be managed, gasses must be contained, and the landfill’s own capacity must be monitored on behalf of the companies and municipalities using the site.

Here are eight ways technology is helping the engineers in charge of waste sites work more effectively.

Putting a Lid on Gas Emissions

Landfills give off lots of gas — and accompanying smells. Waste engineers spend incredible amounts of time finding ways to convert those emissions into something useful while mitigating any downwind fumes that a site’s neighbors could find nauseating.

Fortunately, some of those emissions can be turned into fuel, which is what French company Air Liquide is doing at a site in Mississippi. As Cole Rosengren at WasteDIVE reports, Air Liquide — which is just putting the final touches on its purification plant — expects to begin purifying the methane from that site, via a polymeric membrane, into around 1,300 mmBTU per day.

The company says its membrane technology can create biomethane with up to 99 percent purity.

Measuring Emissions with Drones

Drones have been a huge boon to heavy industry because they offer so many versatile ways to collect data. The same is true in the solid waste industry.

For sites that emit gases, “drones offer a sampling platform from which to traverse the atmosphere in three-dimensions relatively rapidly (at the spatial scale of landfill sites, anyway),” AWE International writes.

What’s more, with a single drone or a fleet of drones getting real-time samples in the air, you can control for variables such as wind speed and get a much more accurate estimate of exactly how much greenhouse gas emissions a specific site is responsible for, the authors write.

Therefore, drone data collection is poised to deliver some big ecological wins in this industry.

Bio-Covers to Reduce Methane Emissions

Researchers at the Technical University of Denmark are experimenting with materials they call Bio-Covers to reduce the amount of methane landfills emit into the air. The idea is simple: Cover a site with compost containing the right microorganisms, which can convert the rising methane into CO2, a gas that contributes exponentially less to any greenhouse effects in the atmosphere.

“The Danish Bio-Cover scheme for the control of methane emissions is unique worldwide in providing funding for this,” writes the consultancy NIRAS, which is cooperating with the university on this project and using drones — exactly as noted above — to help measure methane outputs.

“The scheme is administered by the Environmental Protection Agency, and the funding is estimated to be sufficient for controlling and mitigating methane emissions from approximately 100 waste disposal sites and landfills in Denmark. Currently, there are a total of seven pilot projects underway in Denmark.”

Using Materials to Control Odors, Too

More tangibly than greenhouse emissions, at least for nearby residents, landfills can give off some foul smells. Dr. Laura Haupert, Director of Research and Development at OMI Industries, recently wrote about how that company is implementing a solution for landfill odor it calls Ecosorb.

Ecosorb technology combines plant extracts, water and surfactants to lower liquid surface tension to eliminate odors at the molecular level — “without the use of harsh or hazardous chemicals, emission control systems, or masking fragrances,” the blog post points out.

Slippery Slopes: Managing the Liquids in Landfills

Leachate management is an ongoing challenge for solid waste engineers. When water percolates through the contents of a landfill, it becomes a pretty effective vector for introducing pollution into the surrounding earth.

That’s why the liners at the bottom of landfills have become such a serious focus of innovation. Materials engineers are constantly looking for ways to create better liners to contain that leachate.

One of the most promising such liners are made from geosynthetic clay, the team at AGRU writes, because that material is both durable and hydrophobic. Engineers today are using geosynthetic clay (GCL) to create composite liners with geomembranes (GM) that create two layers of leachate protection.

“When using GM alone, even the smallest hole brings leachate directly into the leak detection system with sufficient driving hydraulic head,” the AGRU team says. “The high swelling characteristics of the bentonite clay component in the GCL will work to seal the leak in the GM.”

Applying Geosynthetic Liners to Other Industries

Landfill managers aren’t the only ones who recognize these benefits. Mining engineers at coal mines have begun to use GCLs to help contain wet coal ash, Chris Kelsey writes at Geosynthetica.net.

“The coal ash resistant GCL is a specifically formulated, polymer-enhanced geosynthetic clay liner with granular sodium bentonite encapsulated between two geotextiles,” Kelsey says. “It is intended for containment of the potentially high ionic strength leachates in coal combustion waste applications.

“The polymer enhancement of the bentonite delivers outstanding performance under extreme conditions and chemical attack, making it ideal for lining systems with wet process ash or dry ash storage. This geosynthetic is unique in that high ionic solutions with elevated levels of calcium and sodium have historically been a ‘no-man’s land’ for bentonite-based products.”

Why Some Landfills Intentionally Add Water

One municipality in North Texas, however, is upping the water levels in its landfill. Arlene Karidis at Waste360 has the story:

The city of Denton, Texas, is working with researchers at the University of Texas, Arlington to increase and monitor liquid levels in its landfill. This has two benefits. First, it accelerates decomposition, thereby extending the life of the landfill. Second, that decomposition should triple the amount of useful methane gas released from the site.

The project relies on a novel method of monitoring liquids called electrical resistivity imaging, which lets researchers track the content and movement of moisture in the landfill, giving them precise data that will tell them when to add water and when to hold off.

The Internet of Things Brings a New Level of Intelligence to Sites

The universe of connected devices that comprise the Internet of Things has begun to transform several industries, including manufacturing and home energy management. This same technology, when applied to the solid waste industry, offers whole new ways for managers to gain insights on their worksites.

For example, the city of Atlanta recently hired cloud-based waste management company Rubicon Global to equip its fleet of hauling trucks with the company’s app, which makes it possible for fleet managers to track each truck’s routes and pickups in real-time.

“This cutting-edge suite of new services will enhance operational efficiency, improve customer service, and ensure a consistent level of service citywide,” Rubicon Global writes at Forrester Daily News.

“The insights gathered by Rubicon go beyond route analytics and pickup rates. Our partnership with the City of Atlanta will also provide valuable planning data for the Mayor’s Office of Sustainability, most notably by enabling real-time information on current landfill diversion and recycling rates in support of the city’s zero-waste efforts.”

That kind of intel has benefits beyond the day-to-day operations of a site. For customers — i.e. local taxpayers — this can mean more precise, individualized billing for garbage collection services, the Fluid Gas Handling team at Parker writes, rather than simply charging all taxpayers an average price for collection.

“The system would reward you for reducing waste and increasing recycling and reuse. It is not a unique idea — simple measurements on garbage trucks and smart identification of garbage cans is already being piloted and underway. The ubiquitous presence of connectivity and reduced cost of sensing and cloud storage are enabling and accelerating it.”

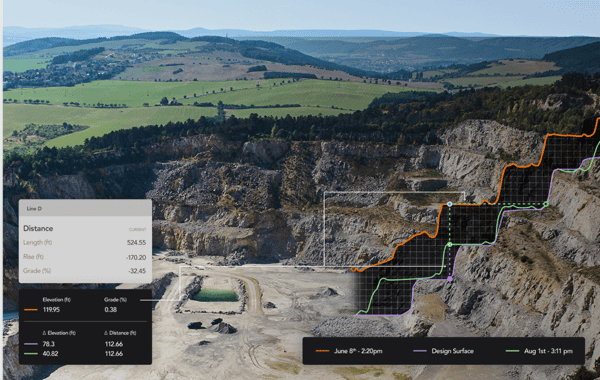

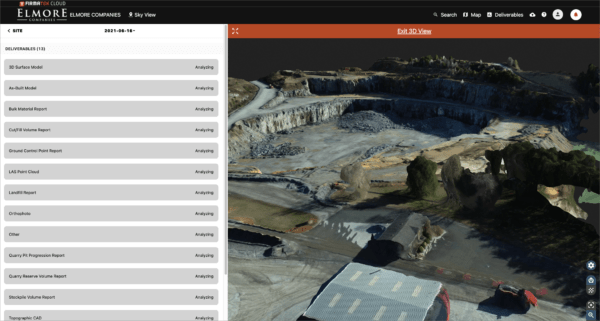

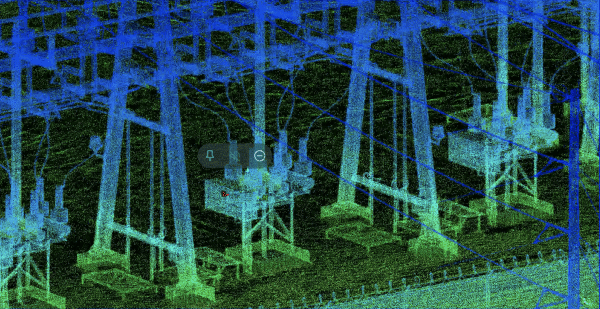

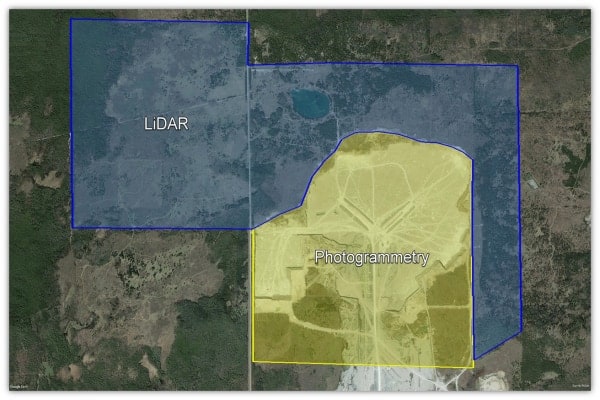

Finally — and this speaks directly to the work we do at Firmatek — a distributed network of sensors means the materials, construction and solid waste industries can start analyzing their sites in more than three dimensions.

“By combining multiple datasets, it’s possible to develop 4D models that enable users to view conditions over time,” TechTarget’s IoT Agenda notes. “This approach provides the ability to detect and measure changes and provides important benefits to applications such as construction, earthworks, agriculture and land administration.”

The TechTarget piece even suggests a fifth dimension, cost, that can be layered over those analyses so that a site manager could easily visualize the resources, time and money needed to move solid materials.

Considered all together, the evolution of technologies that manage emissions, control leachate and monitor landfill sites will make the solid waste industry a very interesting space to watch in the next few years.

images by: ©conceptw/123RF Stock Photo, ©siur/123RF Stock Photo, Hans