By Lauren Elmore. Published in Aggregates Manager.

Stockpile measurements are an integral part of running a successful aggregates business. Operating efficiency and profits depend on stockpile measurements, yet many aggregates operations are guilty of making numerous common mistakes.

Leaders in the aggregates industry know their business, but they don’t generally know the ins and outs of the technology used to measure it. Gathering data can be extremely complex, and a skilled professional can find and address issues in order to deliver the best results possible. To keep everything moving forward in an organization, working with a service company is one of the most effective solutions for gathering and processing data into a usable form.

Stockpile measurements aren’t 100 percent perfect, but operators should focus on making accuracy one of their top priorities. With a more refined picture of stockpiles, an operator can base decisions on sound data instead of deceptive estimates, improving efficiency and boosting profit margins. To solve some of the most common measurement problems, keep the following strategies in mind.

1. Choose the right technology for your needs.

To manage resources, an operator has to measure them accurately. Depending on the types of technologies used, operations are often left with incomplete data sets. They may not be able to measure the entire pile, which means they need to make assumptions that will affect decisions down the road.

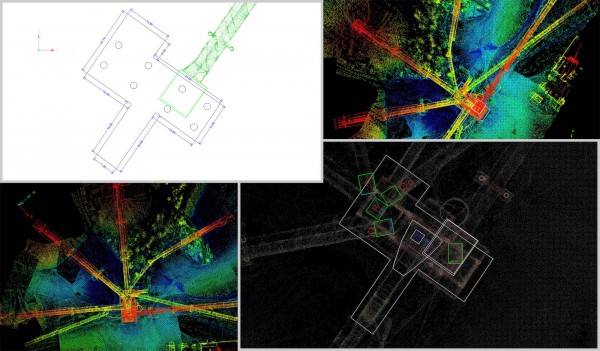

The best way to obtain accurate measurements is to use the right mix of technology. For most sites, a drone or a mix of terrestrial LIDAR and drones will be a good mix. However, if the operator has a very large site (more than 5,000 acres), aircraft-based LIDAR or photogrammetry may be a good option to collect accurate data.

2. Measure consistently.

Infrequent measurements that are only made once or twice per year can also contribute to errors in inventory, and these mistakes will impact operations and sales.

In the aggregates industry, quarries and yards are dynamic environments. Huge machines are capable of moving thousands of tons of material in a single day. Over the course of weeks and months, entire landscapes can change, rendering previous measurements obsolete.

Quarterly or monthly measurements are a good starting point for most operations. Some operations that move a lot of material may need to measure as frequently as weekly in order to obtain a strong understanding of the material they have on the ground.

3. Make adjustments instead of corrections.

Many operations simply correct numbers when they find an inconsistency in measurements. While updating the books to reflect reality is a necessary step, it also fails to take into account the source of the problem.

Instead, adjustments must be made to determine why numbers are off so that the inconsistency doesn’t continue to manifest itself. Density numbers are a frequent source of error — if the density is off by even a tenth of a ton per cubic yard, the inventory measurement may be woefully inaccurate.

Data is revolutionizing our world, and the aggregates industry is no different. Innovative measurement techniques have led to improvements in safety, accuracy, and affordability, encouraging industry leaders to view consistent stockpile measurements as an investment instead of a cost. Accurate measurements give organizations the confidence to make good decisions, ultimately leading to better business outcomes.