By Mark S. Kuhar. Published in Rock Products.

ROGERS GROUP EMBRACES TECHNOLOGICAL EFFICIENCY WITH FIRMATEK’S ENTERPRISE DRONE SOLUTIONS.

Rogers Group Inc. is the seventh largest producer of crushed stone in the United States, according to the U.S. Geological Survey. Headquartered in Nashville, Rogers Group has quarry operations across the Midwest and Southern states.

Rogers Group began using San Antonio-headquartered Firmatek for annual inventory measurements in 2017, and it has since rolled out an Enterprise Drone Solutions Program in partnership with the company.

Firmatek’s technology has given Rogers Group a solution to many inventory management problems, thus allowing the company to focus its time and effort in other areas of its operations. The approach to adapting new technology has also improved the company’s culture of innovation.

Traditional Measurement

Prior to working with Firmatek in 2017, Rogers Group managed its inventory with annual flyovers in combination with proper belt scale and loadout scale calibrations. While that may have kept them in the ballpark, most day-to-day decisions were based off of visual inspections. While this was a valid approach years ago, technology now enables companies like Rogers Group to get accurate inventory numbers on a much more frequent basis.

The goal is to have the products that customers need, when they need them. However, with old technology and infrequent measurements, it is a guessing game. Newer technology can provide a cost-effective way to have better business intelligence on which to base decisions.

Inventory numbers are critical to being an effective supplier of aggregates, as with all commodities. It is important for those making decisions to have an accurate inventory number on which they can base their decisions. Key decisions like, what products to produce and what the balance of products should be in a market area, are critical to maintaining relationships and preferred supplier status in the marketplace.

Rogers Group Out in Front

While many companies in the industry have been exploring drone solutions for inventory measurement and management, Rogers Group is among the first to successfully implement an enterprise-wide program.

Rogers Group partnered with Firmatek to tackle this program. Internally, Rogers Group has committed to improving their technological efficiencies. Their initial focus was in the inventory management sector.

“Rogers Group has always utilized an aerial solution for inventory, but not the management piece,” said Jared Nix, , director of corporate quality control for Rogers Group. “We needed the capability to acquire real-time measurement at the frequency that works best for us. Drones have given us that option.”

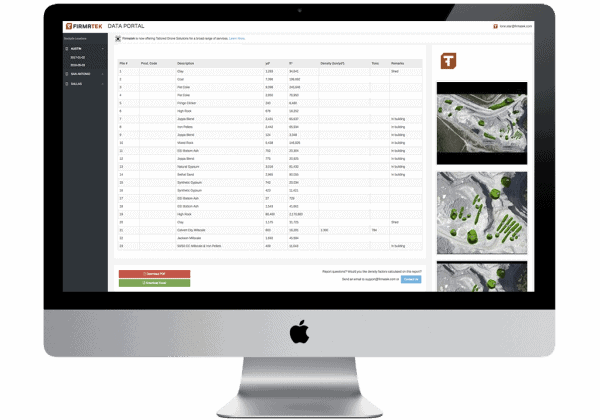

Firmatek worked with Rogers Group to develop an enterprise program that worked for them. The two worked together to develop custom forms, emails and approval processes to meet all of Rogers Groups internal requirements and create an easy and efficient process in order to promote adoption.

At Rogers Group, you need approval from the strategic market area vice president and the director of corporate quality. Rogers Group also has a Risk Management department that gets a form from Firmatek so that they can track the drones and manage their risk easily. That’s the administrative side. There is also an onboarding and training process. Firmatek worked with another provider to run a two-day training session to get a number of pilots up and running quickly.

“Drones fit in our strategy by being another tool for our toolbox of continuous process improvement,” Nix said. “Technology, especially in our industry, has and continues to rapidly evolve over the years. We do our best to stay on the cutting edge and I feel that drone use helps maintain that innovative culture.”

Rogers Group currently has about 15 pilots utilizing 11 drones across the company. Once they have their FAA Part 107 license, Firmatek ships them a drone and they start flying when it is convenient.

Rogers Group requests everything from inventory measurements to ortho photos to pit progressions. Instead of one measurement a year, they are measuring monthly. These frequent measurements help keep the inventory numbers accurate throughout the year and enable them to make more informed business decisions.

“We follow all FAA regulations regarding airspace and flight safety,” Nix said. “We also respect our neighbor’ privacy and confine the flight parameters to our own property. However, we have also provided the drone service to the community during fundraisers and other community outreach activities.”

Why Firmatek

There are a number of drone providers offering products and services to the aggregates industry. Rogers Group chose Firmatek because Firmatek’s innovative, forward-thinking approach to technology complimented its own ideas.

In addition, “It’s simple, fast, accurate, accommodating and most importantly exhaustive,” Nix said. “Firmatek refuses to consider a project deliverable complete until we are completely satisfied with the end product.”

The company has a unique history. Founded in 1988, Firmatek pioneered the use of lasers to measure stockpiles. Since then, it has continued to bring new technology into the aggregate mining industry, revolutionizing the way data is captured and analysis and insights are provided to the industry. In addition to introducing laser measurement to the industry, the company also pioneered mobile LiDAR as a tool to capture data.

With that history of innovation, Firmatek continues that legacy today. They are a national leader in drone solutions for the aggregate mining industry, providing enterprise drone solutions to the largest producers in the country. Firmatek also recently launched their software development department, showing their continued commitment to offering the industry better tools and ways to visualize their data and gain insights and business intelligence from the data.

New Technology

Rogers Group recognizes the importance of embracing technology in this industry, and the company is committed to improving its use and commitment to technological efficiency. The company knows that technology will continue to impact its work, and will see that impact growing exponentially.

The aggregate industry is constantly evolving, demanding more from technology. For example, the workforce is changing, demanding industry-wide innovation, and the speed of information availability is increasing, demanding more from technology.

Rogers Group is excited about the new opportunities that drone technology brings to their organization regarding mine planning, construction and even training. Firmatek is working with Rogers Group to continue to develop new applications and ways to incorporate drones into their operations.

“Firmatek is a service organization, and we enjoy partnering with clients to find solutions,” said Lauren Elmore, president of Firmatek. “In fact, in September we worked with two clients, including Rogers Group, doing on-site presentations and working sessions to continue to develop new solutions and educate the organizations about the technology and how to use it effectively.”

So what does the future hold?

“The sky is the limit, pun intended,” Nix said. “One of the strongest appeals to me for drone use is its untapped potential. I am constantly being asked by folks within Rogers Group, ‘can we use the drone for this, or for that?’”

And almost every time the “this” is a new concept and the answer ends up being, “yes.”