By Lauren Elmore. Published in Rock Products.

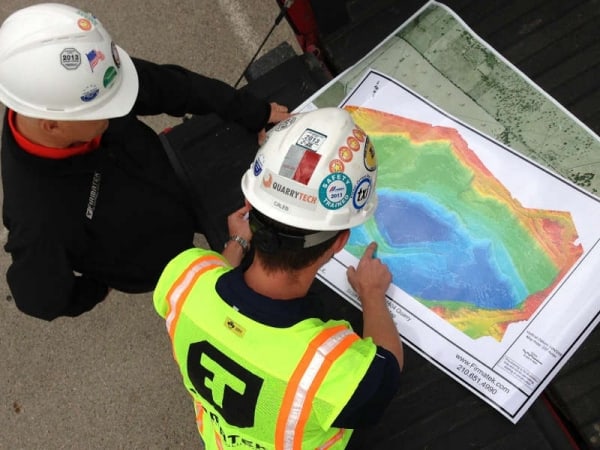

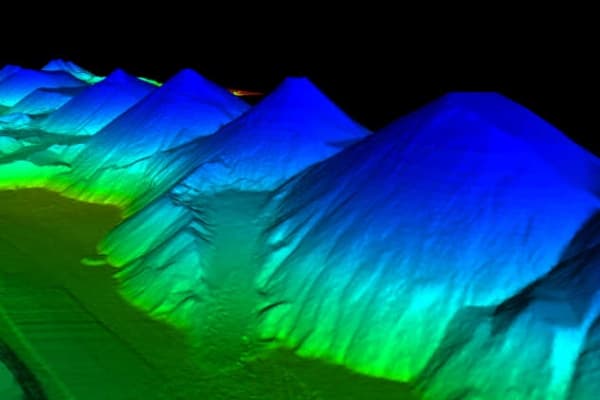

Gone are the days when decision makers in the aggregates industry had to rely on guesswork to determine whether they could meet a client need. With the advent of drone technology, the investments needed to take inventory measurements has been significantly reduced, which means companies can perform these inventories on a regular basis and ensure decisions are being made based on numbers that are as accurate as possible.

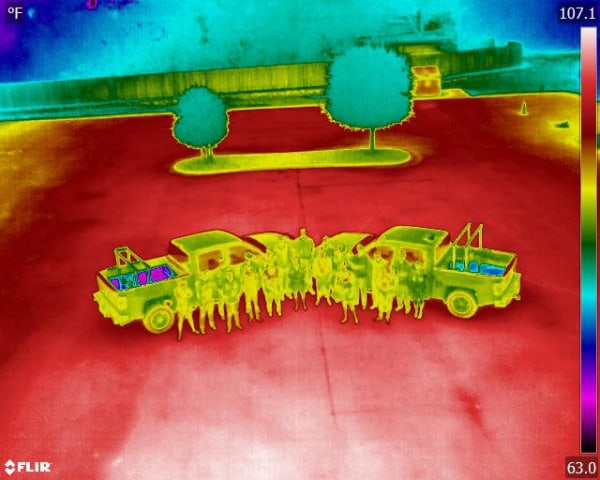

Not surprisingly, drone adoption has been accelerating throughout the aggregates industry, and additional benefits are being realized. Mines are safer because data collectors are out in the field for less time, and drones are proving to be valuable tools for planning how a mine will evolve as production continues. Because of the amount of valuable information they provide, drones are typically used by individuals in leadership roles, such as plant managers.

Some companies have even hired full-time drone pilots. Although this practice remains relatively rare, it will likely increase over the next several years as drones become more of a staple in everyday life. Sales in 2018 are forecast to reach 3.7 million units, which is a 20 percent increase from 2017.

As technology continues to steadily improve, there are fewer reasons not to incorporate drones into the aggregates environment. For executives in this industry, it’s imperative to begin preparing even their most tech-challenged employees for a drone-filled future. These four tips will provide an excellent starting point:

1. Get professional training. Anyone can learn to operate a drone, but professional training will help individuals become familiar with the equipment and processes without having to make the common, and easily avoidable, mistakes that self-taught drone pilots inevitably make. Training from professionals prepares employees in less time, and it pays dividends in the future because it typically includes access to valuable support personnel after classes have concluded.

In order to legally fly, drone pilots will need to pass a Part 107 Certification Test. A class isn’t mandatory, but it’s a best practice to ensure participants pass the exam. The exam preparation will cover around 20 hours of material, including rules and regulations, and then learning to fly will require another 2.5 hours, including videos and in-flight training. Ultimately, professionally trained pilots will be the most confident and competent, and they’ll be better equipped to deliver maximum value with an exciting new technology.

2. Communicate the benefits. Even the most tech-savvy employees tend to balk at change, but putting it into context helps tremendously. While the prospect of drone adoption initially seems daunting, when employees understand the benefits, they’re much more willing to take a chance on new technology.

In the aggregates industry, being able to easily and cost-effectively update mine plans and measure inventories on a frequent basis helps operators make more informed decisions and focus on more important issues. So technology won’t necessarily replace jobs- it will just help employees do their jobs more efficiently.

3. Keep it simple. Forget the big, complicated drones. For most tasks in the aggregates industry, we favor the DJI Phantom 4 Pro for its versatility and simplicity. This affordable drone makes learning how to fly much easier than some of the more complex options, and you can create pre-set flight plans that allow the drone to operate on autopilot. While a company might eventually upgrade to more feature-rich drones, starting simple makes the learning process much less intimidating.

4. Support, support, support. There is no substitute for being able to call a number and speak to a knowledgeable human being on the other end who can help an employee walk through any issues. For example, at Firmatek, our team is available to walk clients through flying the drone or understanding the data. For tech-challenged employees, that safety net is even more valuable because they might not feel comfortable operating a piece of equipment even after completing a thorough training session.

The aggregates industry is changing, and more advanced technology-like the use of drones- is becoming increasingly important. While some employees may be hesitant to adapt to this change, it can not only make their lives easier, but it can also boost your company’s bottom line.