Contributed by VP of Processing, Scott Schiele

At Firmatek, we do a lot of inventory measurements for our clients. Typically, plant managers aren’t thrilled about inventory because of the problems they’ve experienced with past vendors. To ease their apprehension, we strive to be a trusted advisor for our clients and to make the inventory process as easy as possible, from start to finish.

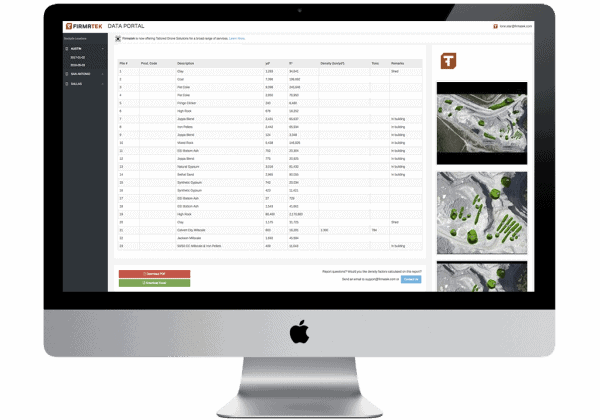

Our workflow comes from years of experience measuring piles. With over 50,000 piles measured in 2017 alone, we have a proven track record of getting it right the first time. We’ve developed many techniques over time and through this process, we learn about any complex piles and how those piles should be measured. We get key information from the plant managers and annotated notes about the piles and their complexities are uploaded to our trained processing staff.

With our share of success, we’ve had our share of issues as well. My experience has shown that most of the issues with inventories fall under three main areas. Over the next few weeks, I’ll be sharing the top issues I’ve seen and how we work at Firmatek to combat them through these effective solutions. To start, I’m going to tackle one of the most common issues we face: base issues.

Base issues can be a problem when measuring stockpiles. Most yards, quarries, and plants that we measure happen to be extremely dynamic environments. In a day, thousands of tons of material can be moved, so when you multiply that over a week, month, quarter, or even a year, it’s safe to say nothing is ever the same from one measurement to the other. Whether the loader is leaving material behind in a pile, so product is not contaminated, or the loader is digging too deep into the base trying to make sure everything is removed, the fact of the matter is the ground is always changing and because of this, using a toe up measurement around the piles has proven to be the most accurate repeatable way to measure most stockpiles. Toe up means the current elevations around the toe of the pile are used and a plane using those elevations is made under the pile to calculate the volume. This takes away the complications of the ever-changing ground and keeps the measurements accurate.

While toe up works on a lot of stockpiles, almost every site has a pile that has been there for many years that’s been added to every year and is now the size of a small mountain. Or they have a pile that has been pushed off a highwall down three benches to where it finally rests. There’s also that one pile that there was no room for, so it was stacked on top of another pile. In cases like this, permanent base is key to having a consistent measurement from survey to survey. Permanent base can be a lot of different things, a best guess model of what the ground looked like before the pile (typically discussed by the site manager), old survey data, old aerial data, or best of all, a drone flight or a lidar scan of the area before the pile began. No matter what that permanent base is, it’s important that those larger or more complex piles be measured against a constant permanent base and that base never changes.

Although the past two methods seem to be contradictory, due to the diverse challenges in the mining environment, both methods are needed to have an accurate inventory. At Firmatek, we have a hybrid approach using both methods to keep our measurements consistent and accurate. The fact is, every site has its own sets of challenges and we have seen almost every challenge when it comes from measuring piles. The Firmatek team has the most experience in the industry. We use top of the line software and hardware to make decisions intelligently and accurately. We are always happy to show clients how we measured the piles and discuss any changes that may need to take place.

Check back next week to learn more about how we tackle another common problem: bad data.