At Firmatek, innovation goes beyond the buzzwords of “cutting-edge” or “state-of-the-art.” For us, progress isn’t only measured in new hardware releases—it’s reflected in the precision of our process, the efficiency of our workflow, and the consistency of our results.

A Look Back: 2023 UAV-Based Methane Testing

In 2023, we deployed our UAV-based Tunable Diode Laser Absorption Spectroscopy (TDLAS) system for methane source detection during a series of controlled release tests. These tests are critical for benchmarking real-world performance of methane detection technologies.

The outcome?

Our system detected approximately 30% of known methane sources at the test site.

For many, this might seem like a decent baseline. But for our team—engineers, pilots, data scientists, and environmental professionals—it was clear: we had more work to do. While the technology showed strong potential, we weren’t content with “good enough.” We recognized an opportunity to radically improve not just the sensor itself, but the methodologyand workflow surrounding its use.

A Transformative Shift: 2024 Testing Results

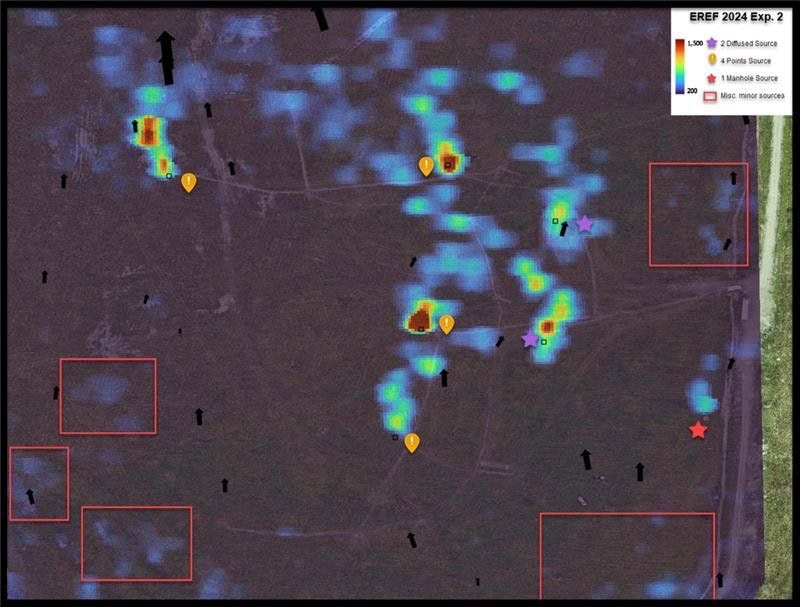

In 2024, after months of iteration, training, and field testing, we returned to the same controlled release facility—this time equipped with a gimbal-mounted sensor platform and a completely overhauled flight and data workflow.

The results were nothing short of remarkable:

-

✅ 100% detection of known methane sources

-

✅ Zero false positives

-

✅ A 10x increase in system sensitivity

These weren’t just minor performance gains. This was a quantum leap in methane detection capability, accuracy, and reliability—all while reducing data collection time and improving operator confidence.

But what led to these improvements? It wasn’t simply a new piece of equipment. It was the product of deep operational experience, refined methodology, and a commitment to constant learning from every mission we flew.

Beyond the Sensor: Why Methodology Matters

At the core of this leap forward is an insight often overlooked in tech-driven industries: Tools are only as effective as the processes behind them.

Our enhanced performance was the direct result of refining how we apply technology in the field. Here are the core areas where we focused our efforts:

1. Flight Line Optimization

In 2023, flight line spacing and density were based on conservative assumptions. We soon discovered that optimal spacing was highly environment-specific. In 2024, we designed tailored flight plans based on topography, wind modeling, and expected source strength—improving both coverage and data richness.

2. Data Filtering & QA/QC Protocols

Raw data can be noisy—especially in complex environments like landfills. We developed more rigorous quality assurance and control protocols that automatically flagged inconsistencies, environmental interference, and equipment anomalies. This helped eliminate false positives and improve confidence in detection outputs.

3. Integrated Visual Inspection

Combining TDLAS data with high-resolution photo and video feeds from the UAV gave our analysts and clients clear, visual context for each detection. This fusion of gas and imagery data enabled faster, more confident validation of methane sources.

4. Faster Data Collection

Thanks to better planning and gimbal-stabilized flight paths, we reduced the time required to survey a site by up to 40%, without compromising sensitivity or coverage.

5. Context-Based Interpretation

Traditional approaches often rely on static ppm thresholds to determine a “hit.” But methane dispersion doesn’t behave in static ways—it’s dynamic, shaped by weather, terrain, and source type. By incorporating contextual parameters into our analysis, we moved away from rigid thresholds and toward more accurate, field-validated detections.

6. The Gimbal Advantage

Mounting the sensor on a gimbal was more than a hardware tweak—it provided stability and directional precision, minimizing signal noise due to UAV pitch and yaw, especially in windy conditions. The result was cleaner, more consistent data—critical for low-level methane detection.

Shared at the 2025 EREF Summit: Raising the Standard

We had the opportunity to present our preliminary 2024 results at the 2025 Environmental Research & Education Foundation (EREF) Summit, a key gathering of landfill and waste management experts. The reception was enthusiastic—and validating.

Our findings reinforced what we’ve long believed: when UAV-based methane detection is paired with the right methodology, it can match or outperform traditional ground-based surface emissions monitoring.

This is more than just a milestone for Firmatek—it’s a signal to the industry that column-based sensing is ready to move from experimental to operational in landfill compliance and optimization efforts.

Why This Matters: The Big Picture

Landfills are among the largest anthropogenic sources of methane—a potent greenhouse gas. Reliable methane detection isn’t just about compliance; it’s about accountability, environmental stewardship, and public trust.

By improving detection rates and reducing false positives, we give landfill operators the information they need to:

✅ Address leaks faster

✅ Improve gas collection efficiency

✅ Stay ahead of regulatory changes

✅ Demonstrate transparency and environmental responsibility

And we make this possible while using non-invasive, UAV-based methods that are safer, faster, and more cost-effective than traditional manual surveys.

What Sets Firmatek Apart

Plenty of companies fly drones. Plenty offer gas detection. Few have combined deep domain expertise, a custom-built data platform, and a culture of iterative refinement like Firmatek.

We don’t just sell a service—we develop a partnership model with our clients, listen and adapt. And we apply the lessons of every dataset to the next one.

Every time we fly, we learn something new. Every time we detect methane, we validate our approach. That’s the cycle we’re committed to—and it’s what drives our results.

Final Thoughts

This breakthrough wasn’t about luck or flashy hardware. It was about refining the method, applying the science, and doing the hard work to bring better methane detection to the field.

As environmental standards tighten and expectations rise, we’re proud to be on the frontlines of innovation—not just with the tools we use, but with the care and intelligence we apply behind the scenes.

Because at Firmatek, we’re building smarter systems that make every dataset count.